Category: Drying equipment

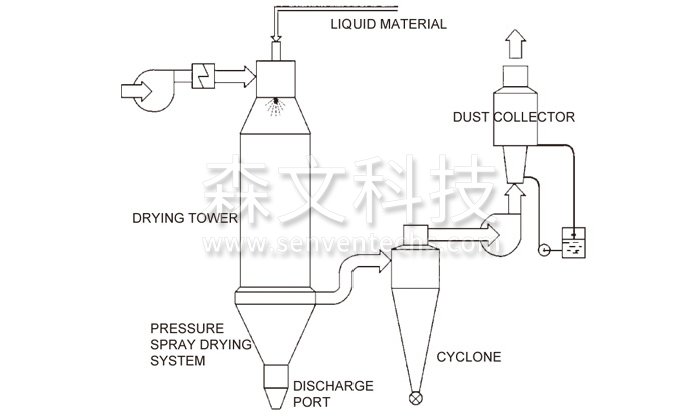

Introduction: Product IntroductionThis unit is a device that can simultaneously complete drying and granulation. According to the process requirements, the pressure, flow rate, and nozzle size of the material liquid pump can be adjusted to obtain the required spher…

+86-15861151117

+86-15861151117

Spray drying granules:

◎ Chemical industry: including catalysts, resins, synthetic laundry detergent, oils and fats, ammonium sulfate, dyes, dye intermediates, white carbon black, graphite, ammonium phosphate, etc.

◎ Food: Amino acids and analogues, seasonings, proteins, starch, dairy products, coffee extracts, fish meal, meat essence, etc.

◎ Pharmacy: traditional Chinese patent medicines and simple preparations, pesticides, antibiotics, pharmaceutical granules, etc.

Ceramics: magnesium oxide, porcelain clay, various metal oxides, dolomite, etc.

◎ spray granulation: various fertilizers, alumina, ceramic powder, pharmaceuticals, heavy metal superhard steel, fertilizer, granular laundry powder, traditional Chinese patent medicines and simple preparations.

◎ spray cooling granulation: amino fatty acid, paraffin, glyceride, tallow, etc. Spray crystallization, spray concentration, spray reaction and other aspects are often used.

| model | 单位 | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| Water evaporation capacity | kg | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| Overall dimensions( Ф× H) | mm | 1600×8900 | 2000×11500 | 2400×13500 | 2800×14800 | 3200×15400 | 3800×1880 | 4600×22500 |

| High pressure pump pressure | mPa | 2~10 | ||||||

| power | KW | 8.5 | 14 | 22 | 24 | 30 | 82 | 30 |

| inlet air temperature | oC | 140~350 | ||||||

| Product moisture content | % | <5 (up to 0.5) | ||||||

| Material recycling | % | >97 | ||||||

| electrical heating | KW | 75 | 120 | 150 |

When the temperature is lower than 200, please refer to the actual technology |

|||

| Electric heating steam | Mpa+KW | 0.5+54 | 0.6+90 | 0.6+108 | ||||

| hot blast stove | Kcal/h | 100000 | 150000 | 200000 | 300000 | 400000 | 500000 | 1200000 |

★The above evaporation capacity is the upper limit of evaporation capacity.

Factors affecting the drying of drying equipment mainly include the following aspects:first, TemperatureTemperature is on…

Controlling the temperature and humidity of the drying equipment is the key to ensure the stability of the drying process…

Selection of suitable high-speed spray dryer needs to consider a number of aspects, the following are some key factors:Fi…

Hotline: +86-15861151117

Long press to recognize WeChat QR code

SenVen Technology