Category: Drying equipment

Introduction: Product IntroductionThe CT-C series hot air circulation oven is equipped with a low noise, high-temperature resistant axial flow fan, and an automatic temperature control system. The entire circulation system is fully enclosed, which increases the the…

+86-15861151117

+86-15861151117

The CT-C series hot air circulation oven is equipped with a low noise, high-temperature resistant axial flow fan, and an automatic temperature control system. The entire circulation system is fully enclosed, which increases the thermal efficiency of the oven from traditional drying rooms of 3-7% to the current 35-45%, and the thermal efficiency can reach 50%. It has saved a lot of energy for our country and improved the economic efficiency of enterprises. In 1990, the National Medical Administration issued an industry standard with a unified model of RXH.

The heating source includes steam, electric, far-infrared, and electric steam for users to choose from;

Operating temperature: Steam heating at 50-140 ℃, up to 150 ℃;

Electricity consumption, far-infrared temperature 50-350 ℃;

Equipped with automatic control systems and computer control systems for users to choose from;

Common steam pressure 0.02-0.8Mpa (0.2-8kg/m2);

Equipped with electric heating, calculated as 15KW according to Type I, practical 5-8kw/h;

Special requirements shall be explained during ordering;

The price of non-standard ovens is negotiable;

If the operating temperature is greater than 140 ℃ or less than 60 ℃, it should be indicated when ordering;

The size of our factory's baking trucks and baking trays is unified and interchangeable;

Oven size: 460 × six hundred and forty × 45 (mm).

Most of the hot air is circulated inside the box, with high thermal efficiency and energy conservation. By utilizing forced ventilation, there is an adjustable air distribution plate inside the box, which ensures uniform drying of materials. The heat source can be steam, hot water, electricity, and far-infrared, with a wide range of options. The whole machine has low noise and balanced operation. Temperature control, easy installation and maintenance. It has a wide range of applications and can dry various materials, making it a universal drying equipment.

| Industry standard models |

technical parameter Model specifications |

Each drying amount (kg) |

Allocated power (kw) |

Steam consumption (kg/h) |

Heat dissipation area (m2) |

Air volume (m3/h) |

Temperature difference between upper and lower parts (℃) |

Equipped with baking tray |

Overall dimensions Face width × depth × high |

Supporting drying truck | Equipment weight |

| RXH-14-B | CT-Ⅰ | 120 | 1.1 | 20 | 20 | 2800 | ±2 | 48 | 2430×1200×2375 | 2 | 1200 |

| RXH-27-B | CT-Ⅱ | 240 | 2.2 | 40 | 40 | 5200 | ±2 | 96 | 2430×2200×2433 | 4 | 1500 |

| RXH-41-B | CT-Ⅲ | 360 | 3 | 60 | 80 | 8000 | ±2 | 144 | 3430×2200×2620 | 6 | 2000 |

| RXH-54-B | CT-Ⅳ | 480 | 4 | 80 | 100 | 9800 | ±2 | 192 | 4460×2200×2620 | 8 | 2300 |

| RXH-5-C | CT-C-O | 25 | 0.45 | 5 | 5 | 3450 | ±2 | 16 | 1130×1100×1750 | 0 | 800 |

| RXH-7-C | CT-C-ⅠA | 50 | 0.45 | 10 | 10 | 3450 | ±2 | 24 | 1400×1200×2000 | 1 | 1000 |

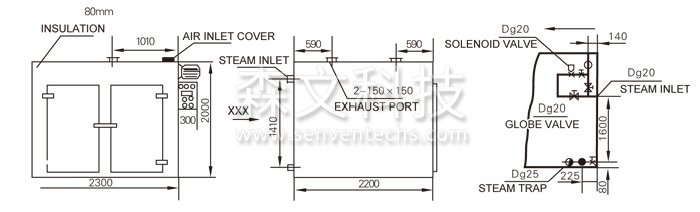

| RXH-14-C | CT-C-Ⅰ | 120 | 0.45 | 18 | 20 | 3450 | ±2 | 48 | 2300×1200×2000 | 2 | 1500 |

| RXH-27-C | CT-C-Ⅱ | 240 | 0.9 | 36 | 40 | 6900 | ±2 | 96 | 2300×2200×2000 | 4 | 1800 |

| RXH-27A-C | CT-C-ⅡA | 240 | 0.9 | 36 | 40 | 6900 | ±2 | 96 | 4460×1200×2290 | 4 | 1800 |

| RXH-41-C | CT-C-Ⅲ | 360 | 1.35 | 54 | 80 | 10350 | ±2 | 144 | 3430×2200×2000 | 6 | 2200 |

| RXH-42A-C | CT-C-ⅢA | 360 | 1.35 | 54 | 80 | 10350 | ±2 | 144 | 2300×3200×2000 | 6 | 2200 |

| RXH-54-C | CT-C-Ⅳ | 480 | 1.8 | 72 | 100 | 13800 | ±2 | 192 | 4460×2200×2290 | 8 | 2800 |

| RXH-25-A | Efficient high temperature far infrared sterilization oven power matching is carried out according to temperature requirements | 1200×1000×1600 | 1 | 1200 | |||||||

Suitable for heating, solidification, drying and dehydration of materials and products in industries such as pharmaceuticals, chemicals, food, agricultural and sideline products, aquatic products, light industry, heavy industry, etc. Such as raw materials, raw medicines, traditional Chinese medicine slices, extracts, powders, granules, granules, water pills, packaging bottles, pigments and dyes, dehydrated vegetables, dried fruits and melons, sausages, plastic resins, electrical components, baking paints, etc.

Next: Medicinal GMP oven

Factors affecting the drying of drying equipment mainly include the following aspects:first, TemperatureTemperature is on…

Controlling the temperature and humidity of the drying equipment is the key to ensure the stability of the drying process…

Selection of suitable high-speed spray dryer needs to consider a number of aspects, the following are some key factors:Fi…

Hotline: +86-15861151117

Long press to recognize WeChat QR code

SenVen Technology